PTFE - Technical section

PTFE

Fine coagulated powders from dispersion polymerization

Properties

PTFE fine powders (Homopolymer and modified) are produced from dispersion polymerization and subsequent coagulation and drying. Primary particle size of about 0,2 micron gives to the powder aggregates a very high specific surface area that allows to be processed by paste extrusion for the production of tubes and AWG. Some modifications of the polymer structure improve processability and properties of the tubes obtained by paste extrusion, like clarity, flexibility, permeability and porosity.

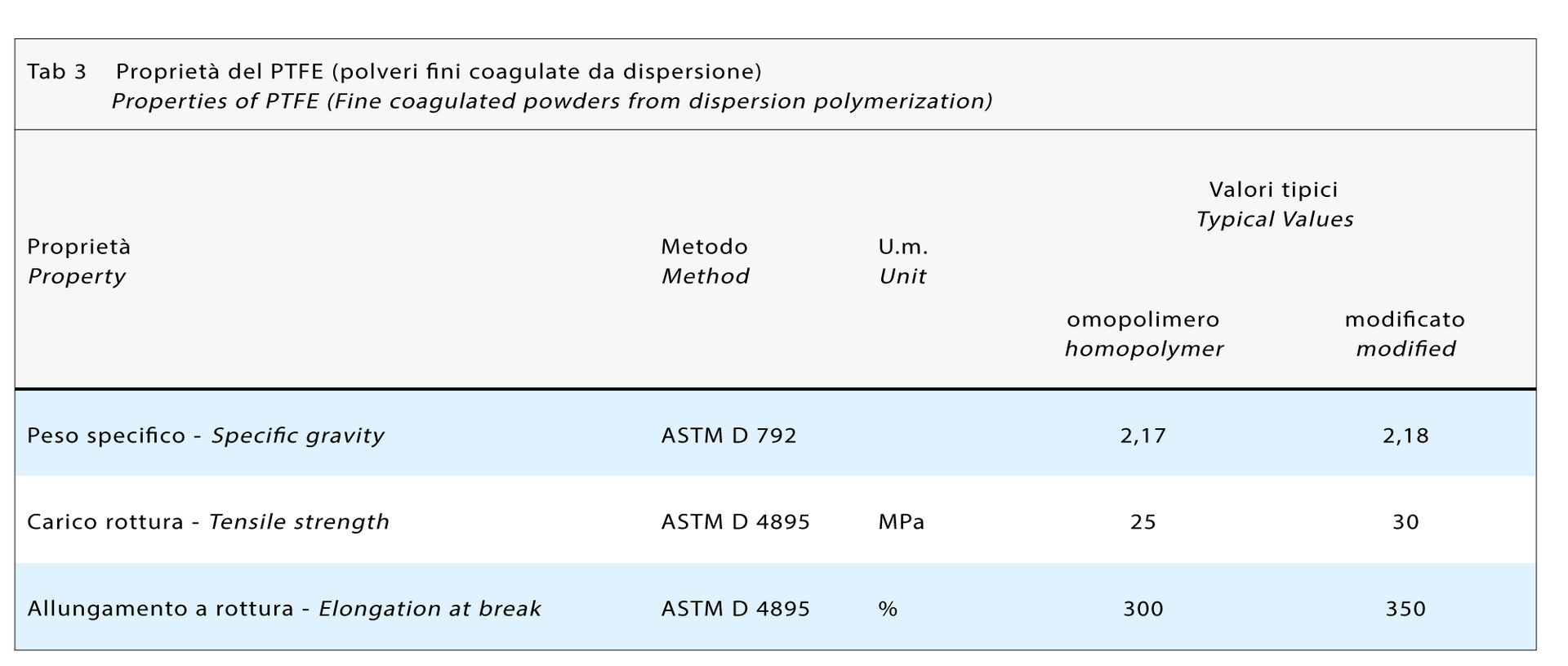

In table 3 are reported some typical properties of PTFE fine coagulated powders.

Applications

Paste extruded PTFE tubings can be used in a temperature range from -200°C (-392°F) up to 250°C (482°F) in static conditions.

These can be used in an extremely wide range of applications: Biomedical, Aerospace, Electrical, Electronics, Household Appliances, CPI and Automotive. Market demand of superior quality PTFE tubing is increasing more and more. GAPI production systems and control can ensure the highest quality and consistency in terms of properties and performance. PTFE Thin Wall Tubing can be supplied in different colours and with special fillers. Special dimensions and tolerances can be produced on request.

Working conditions

In static conditions the upper working temperature limit is 250°C (482°F). Under dynamic conditions the limit has to be reduced to 200°C (392°F).

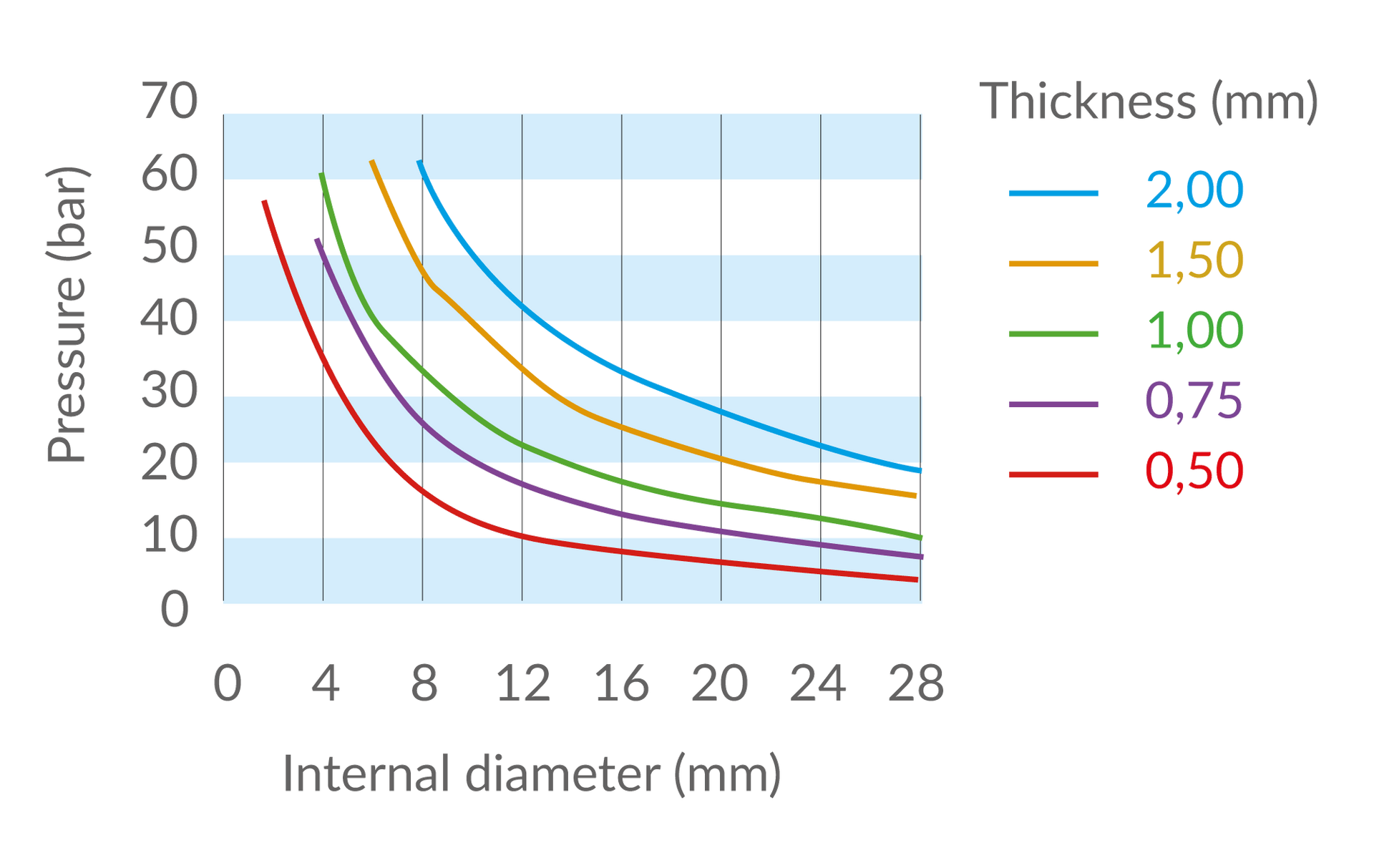

Working pressure is related the burst pressure, tubing sizes and temperatures involved.

The diagram nr 1 reports burst pressure values related to tubing sizes at room temperature.

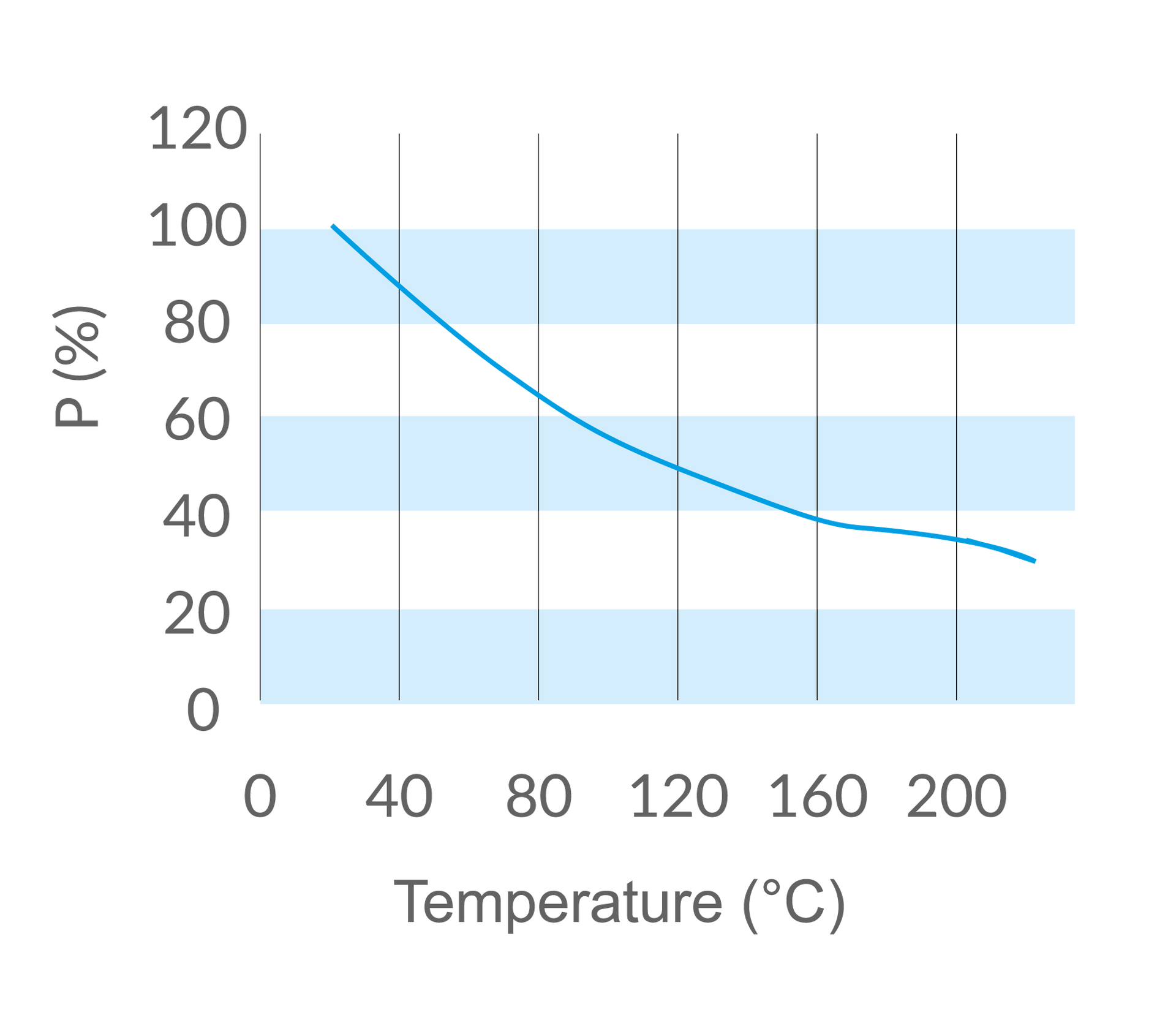

Working pressure of PTFE tubing, when temperature increases, has to be lowered by a given percentage, as per diagram nr 2.

Diagram 1

Diagram 2

Assembly prescriptions

Sharp bending to prevent collapse of the tubing wall has to be avoided during assembly, these can result in a limitation of the flow and some times the tubing may crack.

Minimum bending radius

Minimum bending radius of PTFE Thin Wall Tubing depends on many factors; the most important are: dimension, working temperature, applied pressure and pressure fluctuations. Of less importance the nature of fluid conveyed.

Roughly the minimum bending radius (at 20°C-68°F)

depends on OD and wall thickness. If wall thickness is 1 mm it can be considered:

Rmin mm = 9 to 11 times OD mm (value to be increased at the decreasing of wall thickness).

When special configurations are required it is possible to heat the tubing first, followed by bending and cooling it in the required shape.

A metallic flexible insert to avoid the collapse of the walls can be put into the tubing during bending.

Standards

Dimensions and characteristics of PTFE Thin Wall Tubing are dictated by various Standards for the different application fields.

The most important and widespread Standards are AMS, ASTM , BS, MIL. and ISO 13000/1.

In the following pages you will find tables of dimensions and tolerances of some of the quoted Standards, together with weight per unit length. PTFE Thin Wall Tubing is available in coils of different winding diameters according to their dimensions. Spaghetti tubing is on spools of various dimensions.

PTFE Thin Wall Tubing tolerances are in accordance with ISO 13000-1, para. 4.2.5:

Inner Diameter ID tolerance

< 5 mm ± 0.25 mm

> = 5 mm < 25 mm ± 5 %

Wall Thickness w tolerance

< 1 mm ± 0.1 mm

> = 1 mm ± 10 %

Standard length supplied are 25, 50 and 100 meters (82, 164 and 328 ft).

Tubing can be supplied in special continuous lengths or cut to specific lengths on demand.

Quality

The manufacturing process of PTFE Thin Wall Tubing and AWG has 100% automatic control system, capable of a dimensional fail-free output.

Main physical and dimensional characteristics are

in accordance with the above mentioned specific Standards.

Certifications

PTFE tubing can be certified according with UL Standards for electric insulation and flammability.

Reliability

GAPI products are manufactured with first quality raw materials.

The quality management system is Certified ISO 9001.

Storage of tubes

To ensure a correct storage of PTFE Thin Wall Tubing the original packing has to be kept.

We suggest to stack not more than two/three layers of bags.

PTFE - Technical section